LEAN Thinking

"Lean is the belief that Waste exists in all processes"

Our Aim is to eliminate Waste & only have steps that add Value to clients.

Why Lean matters now?

-

1

Competitiveness

Leaner, efficient processes reduce cost of goods & Services

-

2

Employee Engagement

Bottom up ownership of improvement activities, employees drive change

-

3

Innovation

Less time on Wasteful activities, more time to solve issues for client and improve offering

-

4

Customer Engagement

Happier customers, improved value proposition

-

5

Brexit

Lean is key to government strategy to ensure agility in face of uncertainty.

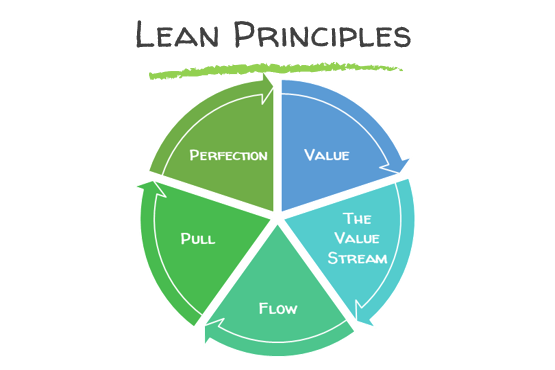

Lean Principles

-

1

Value

Understand & quantify customer value, focus on what is of VALUE to the customer

-

2

The Value Stream

Map all VA, NVA and Waste steps before you implement or change anything

Separate non-value added from value added Map the actions required to produce (value stream) Eliminate activities that do not move the product closer to its final form -

3

Flow

Remove all barriers to flow e.g. delays & defects, Make the remaining value added activities flow smoothly

-

4

Pull

Implement pull systems, Produce only what customers need

-

5

Perfection

Continue to build better and better systems, Continuous Improvement